PREPARATION MACHINERY

- Tablet press

- Capsule filling machine

- Auger filling machine

- Tablet Capsule Counting Machine

- Ampoule filling machine

- Liquid filling machine & piston filler

- Tablet/Capsule bottle packing line

- Vial filling machine

- Emulsifying Mixer

- Tube Filling Sealing Machine

- Bottle cleaning machine

- Coating machine

- Capping & crimping machine

- Stopper washer, drying oven

- Sterilization and drying machine

- Eye Drop Filling Machine

- Homogenizer

- Conveyor

- Bottle Unscrambler

PACKAGING MACHINERY

- Cartoning Machine

- Bag packing machine

- Pillow packing machine

- Blister packing machine

- Labeling machine

- Shrink Packaging Machine

- Suppository production line

- Weighing and packing machine

- Face Mask Production Line

- Horizontal Packaging Machine

RAW MATERIAL MACHINERY

WATER PROCESS MACHINERY

- CZF pure steam genarator

- LD multi-effect distiller

- Medicine Water Blending Tank

- RO water system

- WFI water tank

LAB EQUIPMENT

- Electric scales

- Tablet Hardness Tester

- Tablet Disintegration Tester

- Tablet Dissolution Tester

- Tablet Friability Tester

- Other Lab equipment

PACKING MATERIAL

Home > Products > RAW MATERIAL MACHINERY > CentrifugeCentrifuge

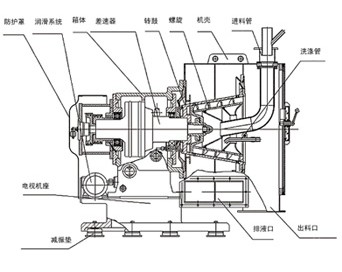

LWL horizontal spiral centrifuge discharge settlement

Main Introduction:

The feed suspension is introduced to the centrifuge through a feed tube and into the feed distribution chamber,and is jetted into the bowl through the hole near the cone point of the scroll.Under centrifugal force the solids separate from the liquid and settle against the bowl wall.while the clarified liquid exits over the overflow screen.The solids in the conical drum are conveyed up from the smaller end to the bigger end while the scroll turns at a slightly different speed.The bigger diameter is,the bigger centrifugal force produces to separate the liquid/solids.The solids are dried when they are drained out the drum.

LWL series scroll discharge screen centrifuge is the one with low enemy consumption.stable performance and good separating effectiveness.It is widely applied to chemical,foodstuffs,salts,mining and pharmacy industries The separation processing from feeding to dewatering,cleaning and discharging is continuous with high processing efficiency and degree of automation.It is the advanced separation equipment.

Given the working principle and its structure,this model of centrifuges is not applied to all materials So it needs to test and analyze the materials before selecting this model.

Technical parameters:

|

|

1.Bowl and scroll and other main parts are made of stainless steel or titanium. |